George Bush Intercontinental Airport

George Bush

Intercontinental Airport

Houston, TX

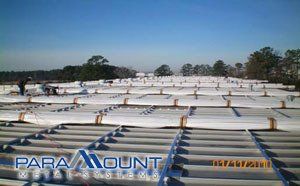

A proposed roofing tear-off of the George Bush Intercontinental Technical Service Warehouse, as a result of Hurricane Ike, led to the specification of the Roof Hugger sub-framing system using a new trapezoidal standing seam. In lieu of tearing off the old metal roof, the Roof Hugger metal-over-metal system was chosen, saving much time and money.

The new 18-inch wide by 3-inch high rib roof system was fastened to Roof Hugger’s pre-notched patented sub-purlins. Existing purlins were spaced at 5’-0” on center, which was not adequate except for in the field of the roof to satisfy newly adopted building code requirements. Additional sub-framing struts spaced at 2’-0” on center had to be installed at the ¼:12 existing roof’s corner and edge zones for 15-feet from the eave, ridge and rakes to satisfy the new IBC 2006 building code wind speed of 130 MPH. The original building’s 1980 design criteria was based on the Uniform Building Code with a wind speed of 100 MPH. The 99,000 square foot re-roofing project was completed in 40 days from mobilization to completion.

| FACILITY NAME: | George Bush Intercontinental Airport Technical Service Warehouse |

|---|---|

| PROJECT TYPE: | Warehouse Retro Fit |

| SYSTEMS ENGINEER: | Paramount Metal Systems — Little Rock, AR |

| SYSTEMS INSTALLER: | Paramount Metal Systems — Little Rock, AR |

| ARCHITECT: | Osborn & Vane Architects — Houston, TX |

| ENGINEER OF RECORD: | E. Concepts Engineers — Houston, TX |

| GENERAL CONTRACTOR: | Axiom Construction Company — Houston, TX |

| SUB FRAMING SYSTEM: | Roof Hugger, Inc. — Odessa, FL Model 242 — 16 GA 50 ksi G-90 4-inch high pre-notched sub purlins punched to fit an existing trapezoidal standing seam roof panel. |

| ROOFING MANUFACTURER: | Metal Building Components, Inc. — Houston, TX 18” x 24" GA Double-Lok with 180 degree seam with a Bone White finish. |